Product

High Efficiency Energy Saving, Quiet Operation

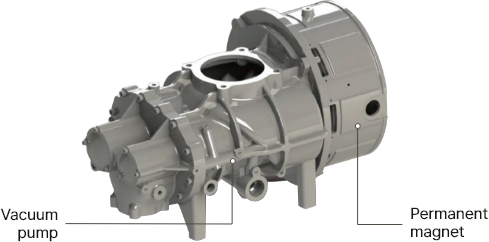

Vacuum Pump

- #Best Efficiency, Energy Efficiency

- #Industry's Best Permanent Magnet Vacuum Pump

The efficient permanent magnet inverter-type screw vacuum pump is optimized in terms of mechanical, efficiency, and control technology.

- Sleek shape and a compact internal structure

- High Quality

- Wide range of capacity control, from 20% to 100%

FEATURE

High-specification Design

Designed to achieve a higher flow rate

Permanent Magnet Synchronous Motor

Increase in motor efficiency and save on electrical energy

Dedicated Inverter

High-cost savings of up to 50% or more

Control System

Safe and efficient control of all compressor functions

High-specification Design

The Y-type line optimized for the operation of an inverter achieves a higher flow rate.

Integrated two-stage separation technology reduces the carryover.

A constant vacuum system can be maintained through frequency conversion, reducing energy wastage.

Maximum vacuum capacity: 29.9inHg

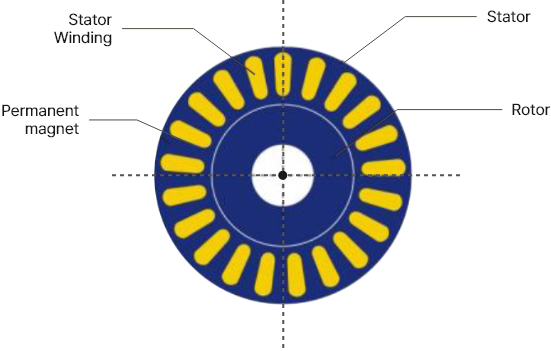

Permanent Magnet Synchronous Motor

High Efficiency

The excitation field of the permanent magnet synchronous motors comes from permanent magnets, and the rotor increases the motor’s efficiency without the excitation current. Compared to the asynchronous variable frequency speed regulations, electrical energy is saved at any rotational speed point, and this advantage is especially evident when the rotational speed is relatively low.

Excellent Energy Efficiency Index

The efficiency and power factor of the permanent magnet variable frequency motors are similar to a horizontal curve. Even when the motor is loaded with 20% of the load, the force energy index of a permanent magnet motor is more than 80% of the total load, which significantly improves the power under load conditions.

Characteristics

- Power Factor : Close To 1.0

- Speed Adjustment Error : 1/30000

- Heat Resistance Temperature : 180℃

- Protection Class : IP65

- Noise : 65dB

Compact and Lightweight

Using a magnetic field created by the high-performance permanent magnet materials, the structure of the motor is simplified, lighter, and smaller, as it is reduced to only 1/3 of the size of a typical asynchronous motor.

High-strength Design

It is designed with oil cooling to withstand temperatures of even 180℃ to protect the magnetic force of the permanent magnet.

Dedicated Inverter

Combines a compressor platform with a state-of-the-art control system.

Provides a soft start function to allow efficient operation through the compressor's capacity range by adjusting to demand while maintaining the optimum starting load precision pressure control.

By eliminating the wasted energy, users can achieve high-cost savings of up to 50% or more.

Control System

Enhanced Control System

- The touch screen controller can control all the functions of the compressor safely and efficiently.

- Touch screen controller monitors the line pressure, oil temperature, and other operating conditions.

- Protects the compressor by alarming and stopping under abnormal conditions.

- Password protection allows you to grant permissions only to the authorized users.

- Possible to monitor the compressor operation data

- Alarm and trip warning

- Programmed maintenance schedule

- Compressor history

- 7-inch full-touch controller

- Built-in multiple language options

- Time, pressure schedule operation possible

- Remote the monitoring possible (optional)

- Built-in standard RS 485 communication

Application Areas

Food Sector

Drying, Concentration, Vacuum Packaging, Meat Processing

Optics

Lens Deposition, Spectroscopy

Semiconductor

Vacuum Chamber, Cleaning Function

LCD

Cleaning Function, Transfer Function

Construction Industry

Concrete Dewatering, Powder/Liquid Transfer

Printing

Paper Transfer

Metal

Heat Treatment, Vacuum Deposition, Surface Treatment

Chemical/Medical Products

Chemical Distillation, Dehydration, Deodorization, Packaging

Other

Plasma, Nuclear Power, Medical Devices

| Model (KRSV) |

Maximum vacuum speed (m³/min) |

Power (kW) |

Extreme Pressure (mbar(A)) |

Inlet size | Outlet size (bar) |

Dimension (mm) | Weight (kg) |

||

|---|---|---|---|---|---|---|---|---|---|

| L | W | H | |||||||

| KRSV11 | 6.3 | 7.5 | 0.5 | DN100 | DN65 | 1215 | 1015 | 1410 | 520 |

| KRSV15 | 8.9 | 11 | 0.5 | DN100 | DN65 | 1215 | 1015 | 1410 | 590 |

| KRSV20 | 12.4 | 15 | 0.5 | DN125 | DN80 | 1315 | 1265 | 1700 | 700 |

| KRSV25 | 15.6 | 18.5 | 0.5 | DN125 | DN80 | 1315 | 1265 | 1700 | 750 |

| KRSV30 | 18.7 | 22 | 0.5 | DN150 | DN100 | 1615 | 1665 | 1890 | 1120 |

| KRSV40 | 27.9 | 30 | 0.5 | DN150 | DN100 | 1615 | 1665 | 1890 | 1260 |

| KRSV50 | 35.6 | 37 | 0.5 | DN150 | DN100 | 1615 | 1665 | 1890 | 1360 |

| KRSV60 | 44.1 | 45 | 0.5 | DN200 | DN150 | 2415 | 1615 | 2165 | 1790 |

| KRSV75 | 55.7 | 55 | 0.5 | DN200 | DN150 | 2415 | 1615 | 2165 | 1900 |

※The above specifications are subject to change without prior notice to improve the product performance.

| Model | KRSV11 | KRSV15 | KRSV20 |

|---|---|---|---|

| Maximum vacuum speed (m³/min) | 6.3 | 8.9 | 12.4 |

| Power (kW) | 7.5 | 11 | 15 |

| Extreme Pressure (mbar(A)) | 0.5 | 0.5 | 0.5 |

| Inlet size | DN100 | DN100 | DN125 |

| Outlet size (bar) | DN65 | DN65 | DN80 |

| Dimension (mm) | 1215 x 1015 x 1410 | 1215 x 1015 x 1410 | 1315 x 1265 x 1700 |

| Weight (kg) | 520 | 590 | 700 |

| Model | KRSV25 | KRSV30 | KRSV40 |

|---|---|---|---|

| Maximum vacuum speed (m³/min) | 15.6 | 18.7 | 27.9 |

| Power (kW) | 18.5 | 22 | 30 |

| Extreme Pressure (mbar(A)) | 0.5 | 0.5 | 0.5 |

| Inlet size | DN125 | DN150 | DN150 |

| Outlet size (bar) | DN80 | DN100 | DN100 |

| Dimension (mm) | 1315 x 1265 x 1700 | 1615 x 1665 x 1890 | 1615 x 1665 x 1890 |

| Weight (kg) | 750 | 1120 | 1260 |

| Model | KRSV50 | KRSV60 | KRSV75 |

|---|---|---|---|

| Maximum vacuum speed (m³/min) | 35.6 | 44.1 | 55.7 |

| Power (kW) | 37 | 45 | 55 |

| Extreme Pressure (mbar(A)) | 0.5 | 0.5 | 0.5 |

| Inlet size | DN150 | DN200 | DN200 |

| Outlet size (bar) | DN100 | DN150 | DN150 |

| Dimension (mm) | 1615 x 1665 x 1890 | 2415 x 1615 x 2165 | 2415 x 1615 x 2165 |

| Weight (kg) | 1360 | 1790 | 1900 |

※The above specifications are subject to change without prior notice to improve the product performance.