Product

EPM2 Series

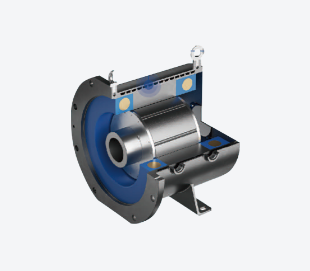

EPM Compressor

- #Extending the service life of the compressor

- #Energy saving system that reduces power consumption

The EPM compressor series uses a magnetic panel pre-filter to reduce the ingress of foreign substances to improve the cooling environment and to lower the noise level with a minimal sealed cabinet design and inlet installation.

- Energy saving with Inverter

- Super premium efficiency IPM motor (IE4 equiv)

- Morse connection design

FEATURE

Motor Power

55 – 110 kw

Discharge Airflow

3.0 – 24.5 m3/min

Pressure

0.7 / 0.8 / 1.0 MPa

EPM2 Series

Magnetic Panel Prefilter

- Improve the cooling environment by reducing the inflow of foreign substances from the outside

- Extend the service life of the compressor

Air cooling system

- Applied the cooling system to ensure all electrical components operate at the optimum temperature

- Minimal enclosed cabinet design and inlet installation to reduce the noise levels

Energy never waste with

The e-stop function immediately stops the motor without waiting for a no-load operation, whenever the load on the compressor is reduced and the air supply becomes unnecessary. An energy-saving system that reduces power consumption by restarting the motor only when necessary. A typical inverter unit needs a few minutes before restarting to prevent the compressor from starting while residual pressure is maintained. It does not stop to maintain the pressure but instead works on an unload standby. On the other hand, the new EPM Series can be started immediately. A wide range of controls can also increase the airflow to shorten the pressure rise time.

High Performance

- PM motor and VSD operate quietly

- Low noise, ideal for indoor shops

- Direct drive reduces the noise levels

High Performance

Super Premium Efficiency IPM Motor

- IE4 Efficiency Class

- Oil-cooled Motor

- Inverter Only

- Permanent Magnet Synchronous Motor

- Protection Class IP65

- Heat Resistance 180℃

Special Morse Connection

- Motor-End Direct Connection

- High Efficiency and Easy Maintenance

- Compact Design

- PM Motor Protection Device Provided

State-of-the-art Screw Airends

- Improved New Rotor Design

- R&D in Japan

- Minimized Pressure Loss

- Equipped with a Large Rotor Four-layer Bearings

- Low-speed Operation (RPM) Guarantees Stable Operation

Innovative Motor Oil Cooling Technology

- Oil Cooling System

- Independent Loop Cooling System

- Independent Cooling Fan

What You Pay Should Be Only For What You Use

EPM compressor can adjust the compressor’s rotation speed according to the factory load’s ever-changing demands by the developed proprietary algorithm.

This allows users to provide the exact flow and pressure needed and achieve maximum energy savings.

This allows users to provide the exact flow and pressure needed and achieve maximum energy savings.

| Model | KW | HP | Capacity (m3/min) | Pressure (BAR) | Dimension (mm) | Weight (Kg) | Size |

|---|---|---|---|---|---|---|---|

| 75EPM2 | 55 | 75 | 3.3 – 11 | 8 | 1800 x 1200 x 1650 | 1450 | RC2 |

| 90EPM2 | 63 | 90 | 3.7 – 12.5 | 8 | 1800 x 1200 x 1650 | 1490 | RC2 |

| 100EPM2 | 75 | 100 | 3.6 – 16 | 8 | 2280 x 1500 x 1950 | 2010 | DN65 |

| 125EPM2 | 90 | 125 | 4.2 – 19 | 8 | 2280 x 1500 x 1950 | 2050 | DN65 |

| 150EPM2 | 110 | 150 | 7.2 – 24 | 8 | 2280 x 1750 x 1690 | 2900 | DN80 |

※The above specifications are subject to change without prior notice to improve the product performance.

| Model | 75EPM2 | 90EPM2 | 100EPM2 |

|---|---|---|---|

| KW | 55 | 63 | 75 |

| HP | 75 | 90 | 100 |

| Capacity (m3/min) | 3.3 – 11 | 3.7 – 12.5 | 3.6 – 16 |

| Pressure (BAR) | 8 | 8 | 8 |

| Dimension (mm) | 1800 x 1200 x 1650 | 1800 x 1200 x 1650 | 2280 x 1500 x 1950 |

| Weight (Kg) | 1450 | 1490 | 2010 |

| Size | RC2 | RC2 | DN65 |

| Model | 125EPM2 | 150EPM2 |

|---|---|---|

| KW | 90 | 110 |

| HP | 125 | 150 |

| Capacity (m3/min) | 4.2 – 19 | 7.2 – 24 |

| Pressure (BAR) | 8 | 8 |

| Dimension (mm) | 2280 x 1500 x 1950 | 2280 x 1750 x 1690 |

| Weight (Kg) | 2050 | 2900 |

| Size | DN65 | DN80 |

※The above specifications are subject to change without prior notice to improve the product performance.