Product

10HP~20HP PM2 Series

Compact Compressor PM2 Series

- #High efficiency PM motor_Constant pressure

- #Easy maintenance_Low noise (68dB) design

The latest oil-cooled motor is even more efficient than the IE3 motor as it uses a PM motor, which operates at a high temperature of 180 degrees. The PM motor, which is guaranteed not to lose the motor’s magnetism, is a highly efficient compressor motor that can vary from 20% to 100%.

- Automatically restarts in case of power failure

- Oil Cooled IP65 Motor

- Robust pipework

- 1 : 1 Direct Drive

- 130L Air Tank and Separate Oil Tank

- Soft Start

- Energy Saving

FEATURE

Service and Maintenance

Simple to service and maintain

Scheduling

On board scheduling for automatic start and stop times

Easy Transportation

Optional wheels for easy installation and positioning

Low Noise

Low noise operation

– 68dB

Bearing-Free Motor

Bearing free motor design

Energy Saving, Compact Compressor PM2 Series

Easy access for maintenance

- Designed with simplicity in mind for the easy handling of the internal components of the compressor

- Reduce the risk of hose breakage with robust and seamless steel tubing

- Increased reliability and reduced service cost by using fewer parts

Low noise operation

- Quiet Operation of the PM Motor and VSD

- Low noise, ideal for indoor workshops

- Reduced noise level with a direct drive

Unique patented air receiver and oil tank

- A unique labyrinth structure reduces the manufacturing costs by using a small part of the receiver as an oil tank.

- Efficient and compact machine size, weight, and footprint through the patented design

Inovance Inverter (VSD)

- The best variable speed drive technology can operate over a wide operating speed range

- Dynamic pressure control provides additional energy savings (within 0.1 bar) with stable pressure control

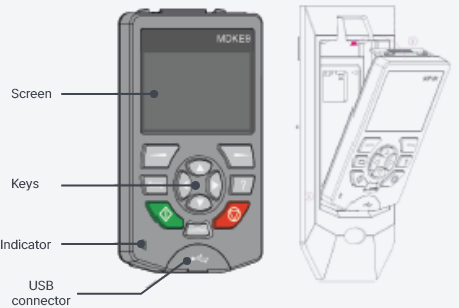

User friendly controller

- Easy operation with the controller using text

- Comes with commissioning, setup, maintenance, and timer functions

- Energy savings possible by setting the start/stop time

Low noise operation

- Following the 2005 work regulations, employees are required to wear the hearing protection equipment when the noise level is above 85 dB. SCR’s PM2 can operate at noise levels below the hearing protection level, enabling machine installation in the workplace.

High ambient running

- The PM2 has a large cooler and fan, ensuring it operates extremely well in high ambient temperatures of up to 45°C.

A compressor for all applications

Because the PM2 operates at a variable speed, it can be used in a wide range of environments, making it ideal for workshops and small and medium-sized manufacturing plants where noise, space, and energy savings are essential.

Small, compact, and expandable, the unique design enables an installation in spaces where compressors cannot usually be installed.

- Flip-top design provides easy front access to consumables for an easy replacement

- No need to install any other facilities and equipment

- No rear ventilation required

- Wheels for easy transport and installation

- Available to be installed close to the back and side walls

| Model | 10PM2 | 15PM2 | 20PM2 | |

|---|---|---|---|---|

| Motor (Hp) | 10 | 15 | 20 | |

| Capacity (m³ / min) | 8kg / cm² | 1.2 | 1.9 | 2.4 |

| Drive | Direct (No – Gear) | |||

| Discharge Connection | Inverter (Variable Speed Drive) | |||

| Dimension (mm) | Length | 1197 | 1197 | 1197 |

| Width | 500 | 605 | 605 | |

| Height | 1125 | 1220 | 1220 | |

| Weight (kg) | 280 | 320 | 320 | |

※The above specifications are subject to change without prior notice to improve the product performance.